Description

Introduction

1. By combining with YAG laser (355nm, 532nm, 1064nm) objective lens, high-precision micromachining can be realized

2. Used in semiconductor processing, liquid crystal repair and other fields

3. It can be embedded in large automated processing equipment or used with a simple stand

Specifications

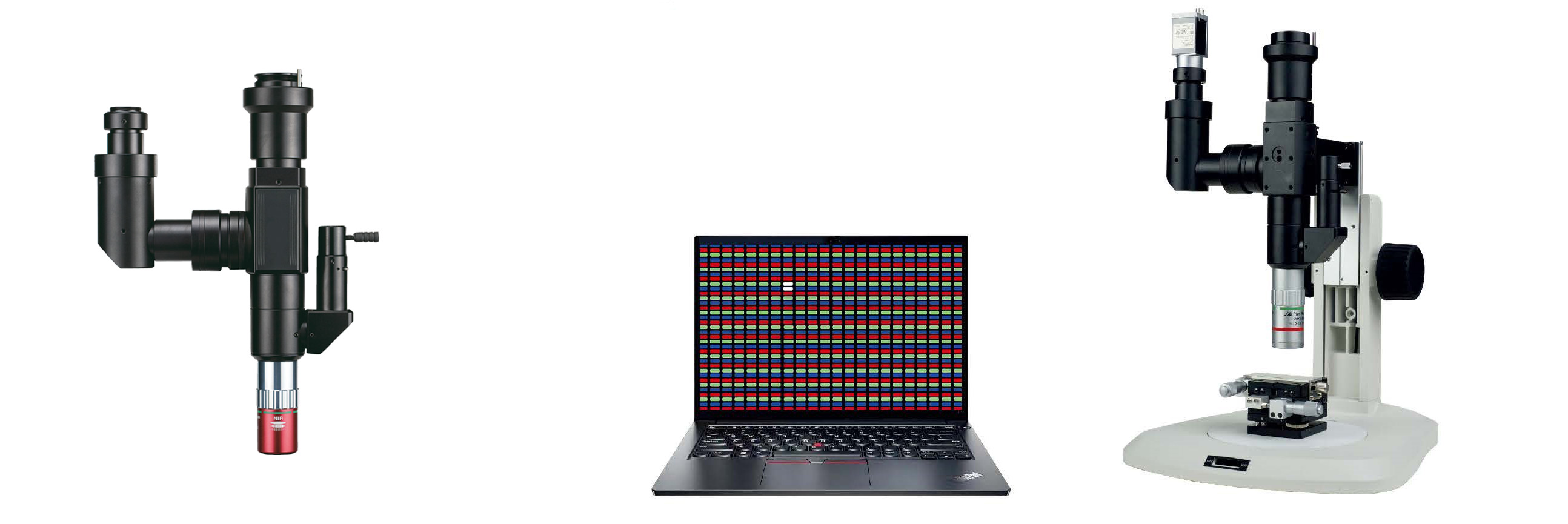

| Camera installation direction | Vertical direction | ||

| Observation imaging | Bright field/Erect image | ||

| Overall system | Camera port | Optical system | Comprehensive magnification 20X (standard equipped with 20X metallographic objective lens) |

| Mount | C-mount (parfocal/centering independent adjustment mechanism) | ||

| Imaging (tube) lens | Built-in f=200 tube lens (visible light and near-infrared correction) | ||

| Laser port | Optical system | Built-in f=200 tube mirror Wavelength: 355/532/1064nm | |

| Mount | YAG laser oscillator | ||

| Polarization unit | can be installed, laser processing can be performed | ||

| Objective | For observation | M Plan Apo, M Plan Apo HR, M Plan Apo SL | |

| For laser processing | LCD Plan Apo NIR, LCD Plan Apo NUV | ||

| Applicable cameras | C mount camera with sensor ≤2/3″ | ||

| Epi-illumination Optical System | Telecentric Illumination with Aperture Stop | ||

| Lighting device (option) | 12V 100W fiber optic lighting | ||

| Main body weight | 1300g | ||